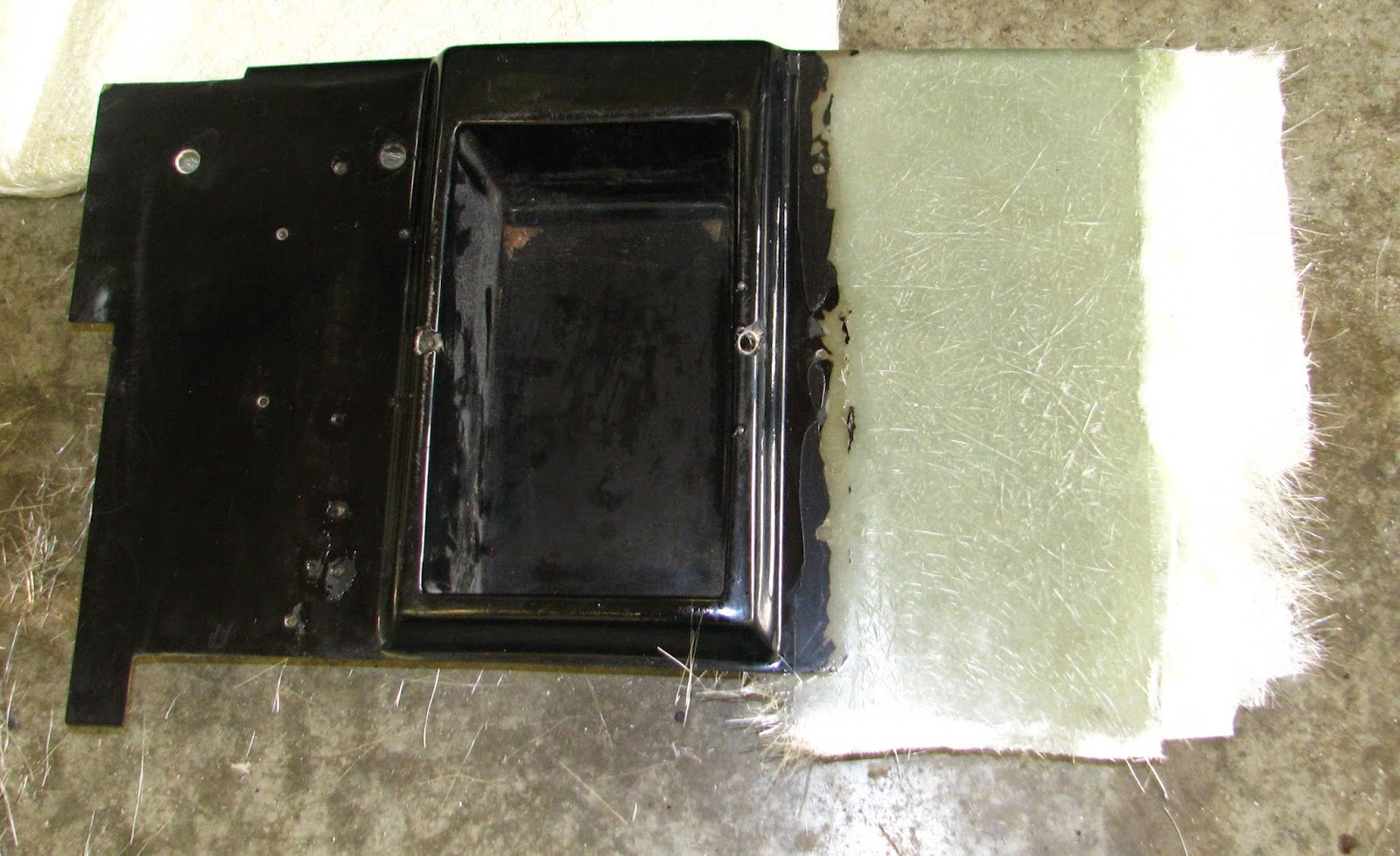

The battery tray and pedal box need some modifications to fit at their new places...

I had to add some GRP at the one side and cut the other side on both parts.

The pedal box bottom:

I have to rebuild this small vertical edge which prevents liquids to run inside over my feet. Two 90° brackets and the GRP in between...

The battery tray from down under:

|

| You see, I had time to take a picture while working with resin... |

As it was about +5°C, the resin will not start to become solid - too cold.

No problem - here is the solution:

Lay a old bed sheet over the parts and place a hairdryer under it - this will give around 40°C and a "perfect" tempered GRP !

After some grinding, filling and smoothing it looked good for the last layer: the top coat.

The structured surface was not what I had expected - but the longer I look at it, the better it looks.

I decided to keep it and use the same technique on the other GRP parts in the engine bay.

I used a foam roller to apply the top coat resin ( it is a specific type of resin, which is not sticky after it is solid ). It has got a silky shine with a light structured surface. Nice.

|

| The spots will vanish by time... |

The GRP job is nearly finished in the engine bay. On task will be to add a "air blocker" between the radiator and the bonnet. The air enters trough the mouth of the bonnet and will be forced to flow through the radiator.

...and if you have a close look above, you see another new part under work....

No comments:

Post a Comment